Innovation and sustainability

An ecological commitment to 360°

OneAir is a company always careful to innovate and renew its solutions, devoting time and resources to propose cutting-edge systems, but always with the utmost attention to environmental sustainability. Over the years we have intensified our commitment to sustainability in order to make the transversal approach to all aspects of our daily work.

Energy efficiency at the heart

OneAir Sustainability Rating (OSR).

For each technology we offer on the market, we pay particular attention to the energy efficiency that this will have compared to the overall system. The level of efficiency is generated by various aspects ranging from energy savings that will enjoy the system to the optimization of the production line and intelligent packaging systems, to the use of durable and sustainable material. These assessments are summarised through the OSR index.

The choice of OneAir materials

Sustainability comes from the constant research and selection of materials from certified supply chains and products from renewable sources. Each material chosen has the mechanical and technological characteristics necessary for the realization of the project and the chemical-physical properties necessary to establish the virtuous circle of recycling-reuse.

The long life of steel. Steel is the most recyclable and recycled material in the world. All steel products or products containing a significant percentage of steel can be reused in their entirety at the end of their life cycle for an infinite number of times because the steel never loses its qualities or the performance characteristics that distinguish from other materials.

The recycled yarn. Fabric diffusers are produced with yarn from recycled PET bottles and packaging, contributing to the reduction of polluting plastic materials in circulation and the extraction of new virgin materials. Being 100% polyester yarn fabrics, the diffusers can re-enter the virtuous circle of recycling once at the end of life.

The regeneration of technopolymer. For our Lumina diffusers we use technopolymer plates made from scraps and PMMA cuttings through a crushing and distillation process: the waste that becomes a new raw material of absolute quality and durability. The same material can also undergo the same process several times.

The OneAir cross ecological footprint

Everything in OneAir is aimed at maximum energy savings and sustainability. From the design phase to the delivery of the material, from energy efficient solutions and products to the choice of technologically advanced raw materials, from careful production planning to the maximum optimization of the production process to the use of self-produced renewable energy sources.

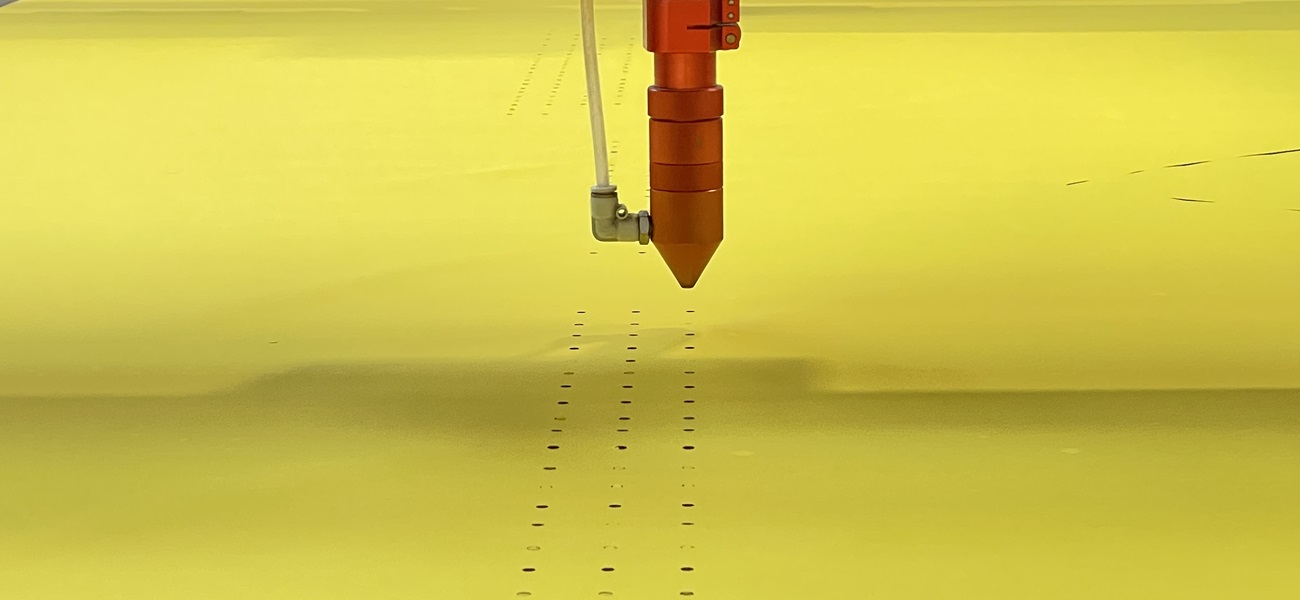

Research and development. The first step towards a responsible proposal is the study of increasingly efficient and effective air diffusion systems: thanks to a dedicated internal department we constantly study new solutions and products for the maximum performance of the HVAC system, we research innovative materials for minimum environmental impact and perfect the industrial design process in a sustainable way.

Design. A OneAir air diffusion system is designed to save electricity thanks to the search for maximum efficiency. In the design phase, we study the characteristics of the environment together with the customer and propose the solution for the best energy efficiency. An optimization of the number of loudspeakers also means less labor, material and handling costs for installation.

Search for materials. Recycled, recyclable and durable: these are the three fundamental properties that a material must have to enter our production chain. In the search for sustainability, we rely on reliable suppliers who guarantee the certified origin and the absolute quality of the raw materials. Using first-class materials means extending the useful life of the product, the first point of the concept of sustainability and reuse.

Packaging solutions. In order to reduce CO2 emissions and therefore the number of means of transport handled for the deliveries we make on national and international territory, we thought of a packaging system that optimizes the quantity of modules on pallets by using smaller diameters inside the larger ones.