Accessory systems for microperforated ducts

Complementary systems integrate the functionality of micro-perforated ducts

In each type of diffuser (fabric, metal or technopolymer) it can be provided the addition of specific solutions, depending on the needs. Our range of accessory systems includes technologies that allow you to:

➤ reduce the "water hammer" effect that can occur in certain cases at the end of the duct (BAS system);

➤ improve and correct the "tangential" component of the air coming out of the holes (CCS system);

➤ provide an insulating barrier during the defrosting phase of an evaporator (CDS system);

➤ standardize the temperature between the occupied area and the upper part of the environment (TDS system).

Discover, in detail, the features and benefits of OneAir accessory systems.

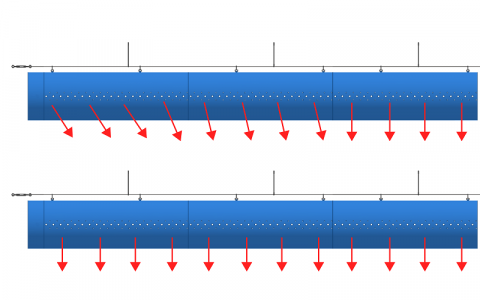

Conical Capture System CCS

The CCS collection system is a special accessory, positioned internally in precise points in textile and metal diffusers that allows to improve and correct the "tangential" component of the air coming out of the holes. It is available in different diameters from 300mm to 1000mm also for existing ducts. In the next image, the first duct does not have the CCS accessory while the second one does.

Improved tangential component. Correction of tangential airflow component up to 50%.

More uniform residual speeds. Uniformity at man height over the entire length of the diffuser.

Improved static pressure. Resulting in air outlet at 90° from the holes.

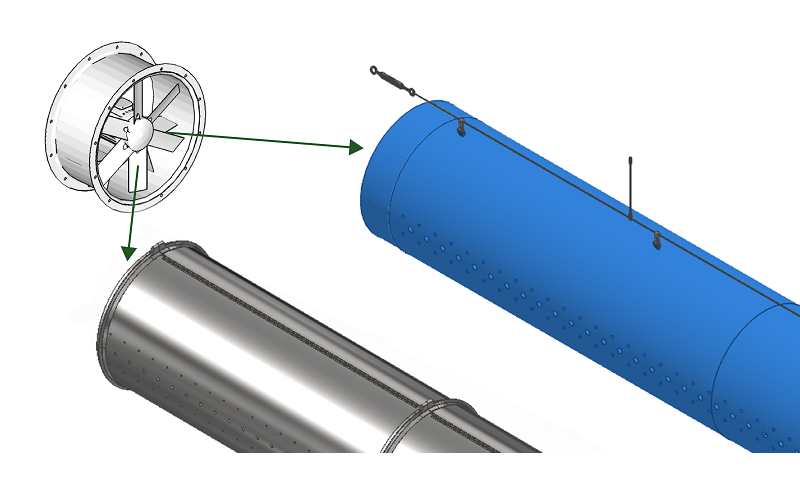

Thermal Destratification System TDS

In large environments but especially large heights such as gyms, production industries or storage warehouses with heating systems often dated there is a need to standardize the temperature between the occupied area and the upper part of the environment to limit heat loss and achieve energy savings. The TDS system involves the installation of an axial fan combined with a high induction destratifier duct and positioned in the upper part of the room.

Temperature uniformity. With more than one fan uniformity is achieved throughout the room volume.

Energy saving. Plant cost 40% lower than traditional systems.

Limited air speed. Low air speeds (0.2m/s maximum) are recorded in the occupied area.

Beat Absorber System BAS

The damping system BAS is a special accessory in fabric, designed for the application to textile diffusers and made by using different fabrics that allows you to reduce the effect of "water hammer" at the end of the diffuser, typical in systems characterized by ventilation units without an inverter or soft-start system. This accessory is available in different diameters from 300mm to 1000mm, also applicable to existing textile diffusers.

Damping of the "water hammer". Reduction of the impact speed during start-up up to 80%.

Maintenance of fabrics. Progressive air entry protects the fabric and seams from damage and prolongs the durability.

Greater silence. Noise reduction characterized by the vibrations of the duct during the start-up phase of the systems.

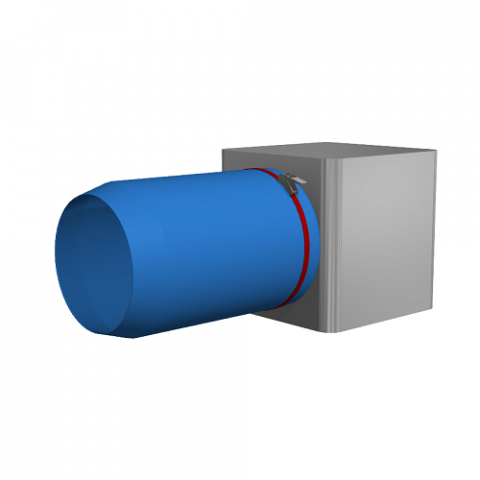

Cooling Defrost System CDS

The defrosting system CDS is a duct in special fabric, water-repellent, conical trunk shape that provides an effective insulating barrier during the defrosting phase of an evaporator substantially reducing the stop time. In addition, it prevents water vapour from entering the refrigerated room during the heating of the evaporator, further helping to stabilize the temperature and humidity. This duct is available in different diameters from 300mm to 1000mm and in different colors.

Fast defrosting cycle. Reduction of the defrosting cycle to 40% resulting in energy savings.

Storage of goods. More stable temperature and humidity eliminates ice on the product improving its storage.

Increased safety. Less ice build-up on ceilings and walls adds more safety to the environment.